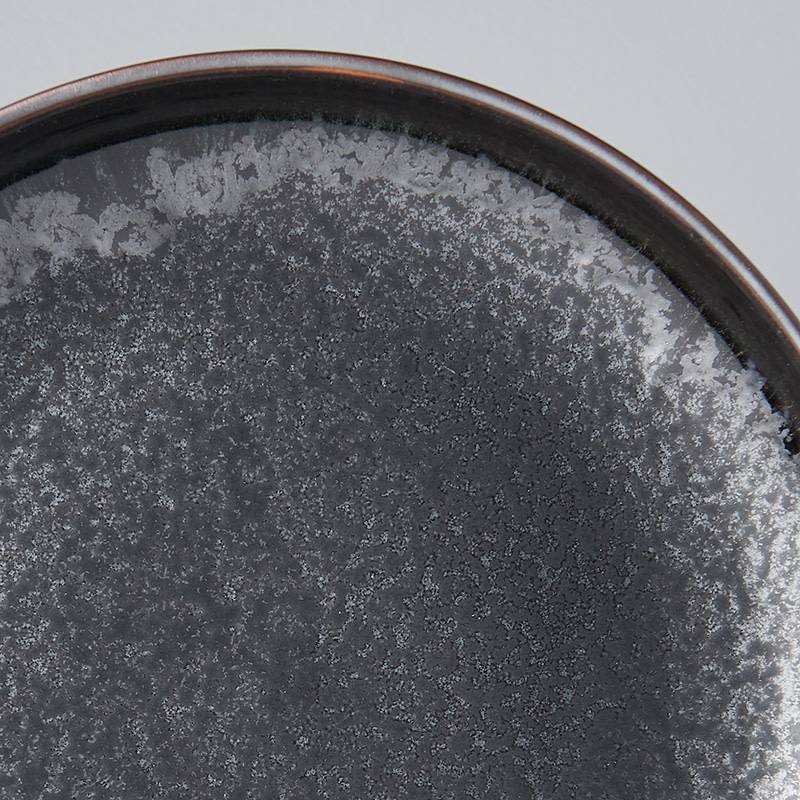

A silvered matt black body, the edge hand-dipped in a rich glossy black. A subtle play of blue and green accents are hidden within the pooling of the glaze.

The Ichi kiln has over 70 skilled craftspeople. They work with a large variety of glazes and use a unique hand-finishing technique to create tableware with an individual touch. We are proud to have been working in partnership with the Ichi kiln for over 30 years.

Slight irregularities in size, glaze and texture reflect the artisan nature of the product and are embraced

Diameter: 22cm

Height: 4.5cm

MIJ products are expertly crafted by artisans in Japan. Japanese pottery is strongly linked to the area of its native resources, this not only includes the clay, but also the form of the product and colours of the glaze.

A brief introduction into the manufacturing process of Japanese tableware:

Clay.

The base ingredient for Japanese ceramic tableware is, of course, clay. Gifu is home to a huge clay basin. Since the 7th century, the craftspeople of Gifu have been able to access this and forge on industry that still thrives to this day. In order to make the clay workable, industrial custom-made machines are used to knead the clay. From there, the clay is used either on the potter’s wheel to form the base shape, or injected into plaster moulds- which produces shapes such as squares and circles.

Sculpted by hand.

For detailed pieces, such as teapots, separate parts are sculpted by hand. Any moulds are then removed carefully and the clay pieces are set aside to dry. Once the clay bodies are dry, an experienced craftsperson will inspect the pieces and remove any unwanted imperfections.

Hand-painted and glazed.

If the clay body requires a motif or pattern, a skilled hand will either paint or carefully apply a transfer-sheet (a thin piece of damp paper with pattern). After the clay has been properly prepared, it is ready for the glazing process. Using tongs, the clay is lowered into the designated glaze, ensuring even coverage. Colour tones are created with various powder dyes, which have been developed and refined over the years.

Into the kiln.

Specific kilns are often renowned for their skill in producing unique or signature glazes. The glazed products are then shelved and loaded onto a cart to be wheeled into a kiln where the final ‘firing’ process occurs. During firing, the kiln is heated slowly to the appropriate temperature and then just as slowly cooled again.

The final finish.

The aim of this process is to heat the objects to the point where the clay and glazes properly marry and ‘mature’ i.e. reach their optimal level of melting in order to set. Only after the kiln has been properly cooled can it be opened. The cart is then unloaded to reveal the finished pieces.

Shipping

FREE standard delivery on orders over £50 (exclusions apply)

FREE collection from our Glossop store

All deliveries are dispatched using either Royal Mail, or DPD. The shipping provider, method & cost will depend on the option chosen at checkout.

Fulfilment Times

We aim to dispatch all orders the following business day and within 3 business days.

*Please note, heavier parcels/larger items may incur additional charges at checkout.

Fulfilment times shown are estimates, we can not guarantee delivery times.

Returns

If you are unsatisfied with your purchase, you may return it to us within 30 days for an exchange or refund.

Please note that we do not cover the cost of shipping or provide pre-paid return labels.

Find out more about returns here